Oil Palm Plantation

The Oil Palm Plantation ERP System is the go-to web solution for today’s dynamic plantation industry. This web-based solution will simplify and streamline workflow so you can manage everything from FFB arrival from the estate to the mill to semi-finished and finished products for sale. It’s designed for the industry, tackling all its rapid changes head-on.

Quality always matters when it comes to customer loyalty. That’s why our oil palm plantation software maintains sky-high standards with its own quality process, ensuring each product exceeds expectations and delights the end user.

Benefits

- – Keep your farm operations running smoothly with an automated system that seamlessly manages thousands of workers employed at the field or block level.

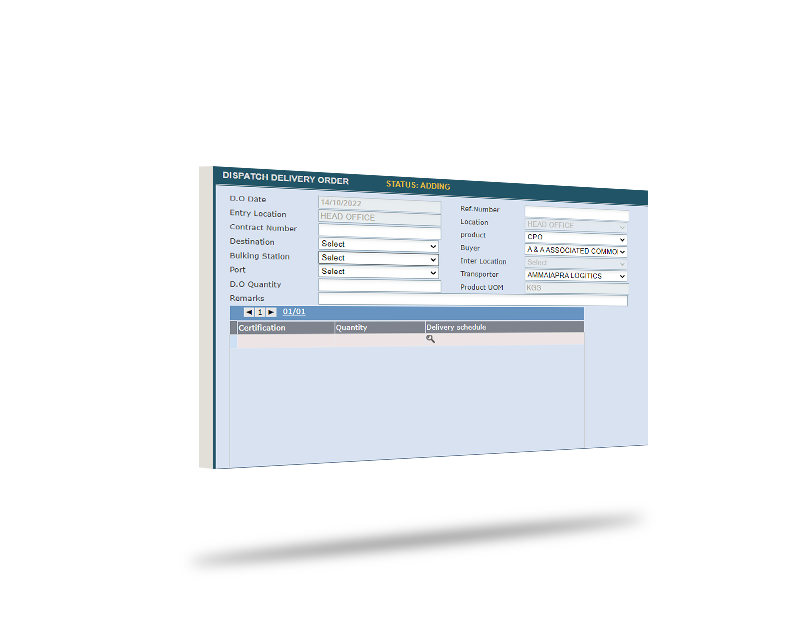

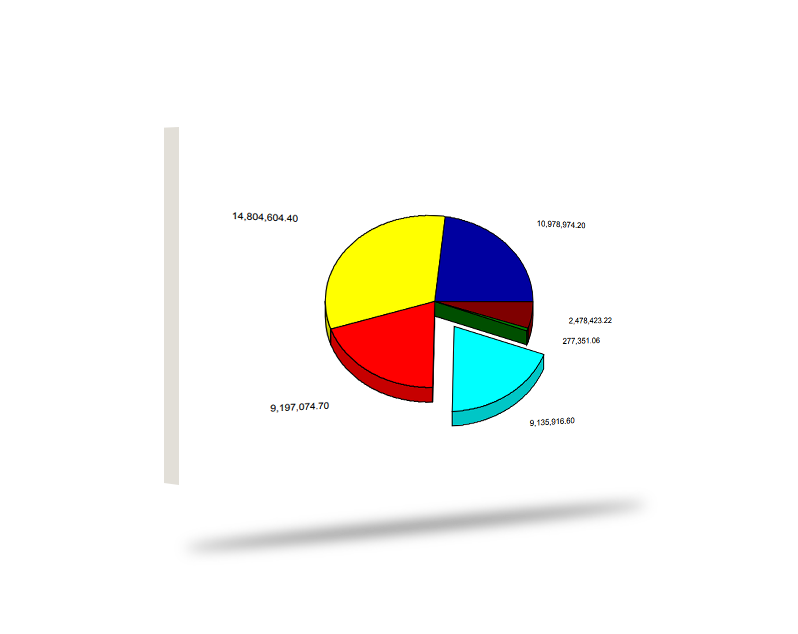

- – Our convenient mass-balancing system keeps track of all Crude Palm Oil, Crude Palm Kernel, and Crude Palm Kernel Oil certificates for an accurate stock assessment.

- – Streamline your oil palm mill and weighbridge management system with the secure, automated integration of our oil palm plantation management software.

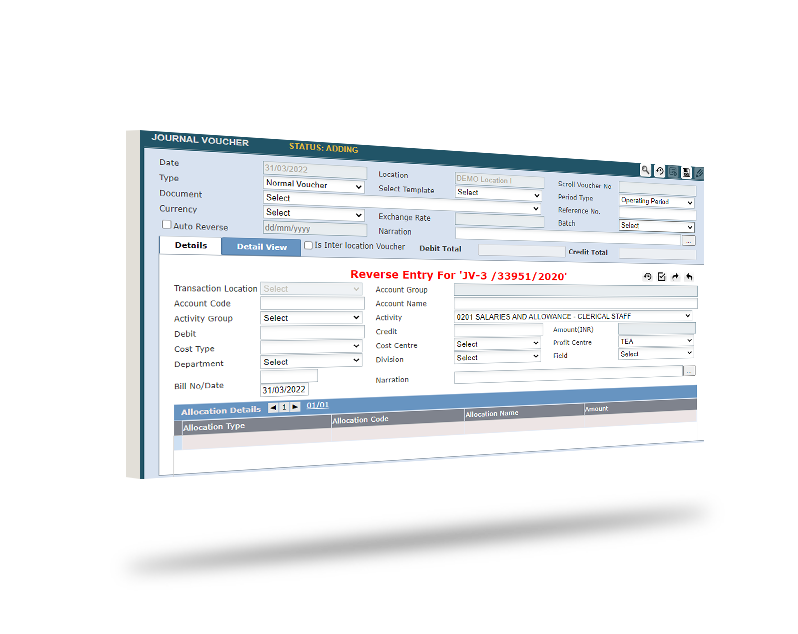

- – Unlock the full potential of our oil palm plantation ERP system by seamlessly integrating with other shared modules and reaping the benefits.

- – Enjoy a seamless connection between your Bulking Station or Tank Farm Management System!

Industries

Vertical - Oil Palm Plantation

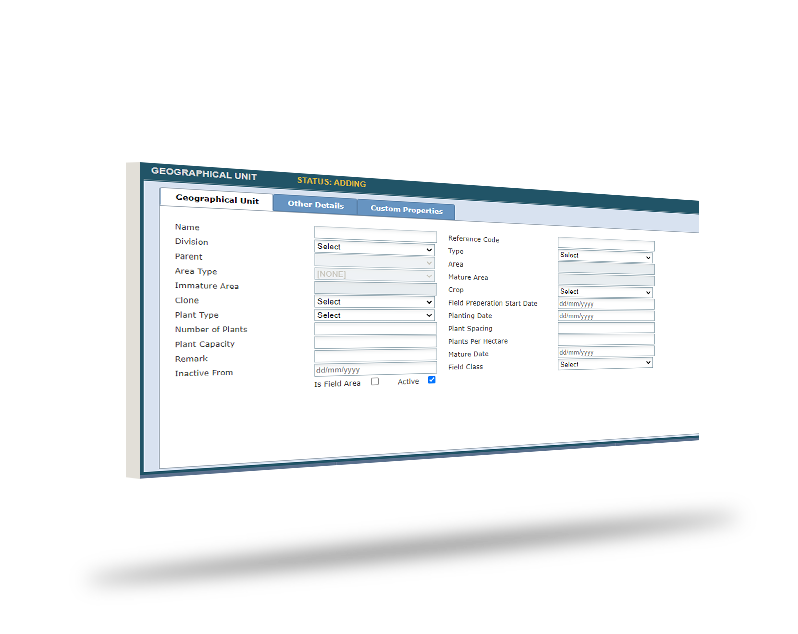

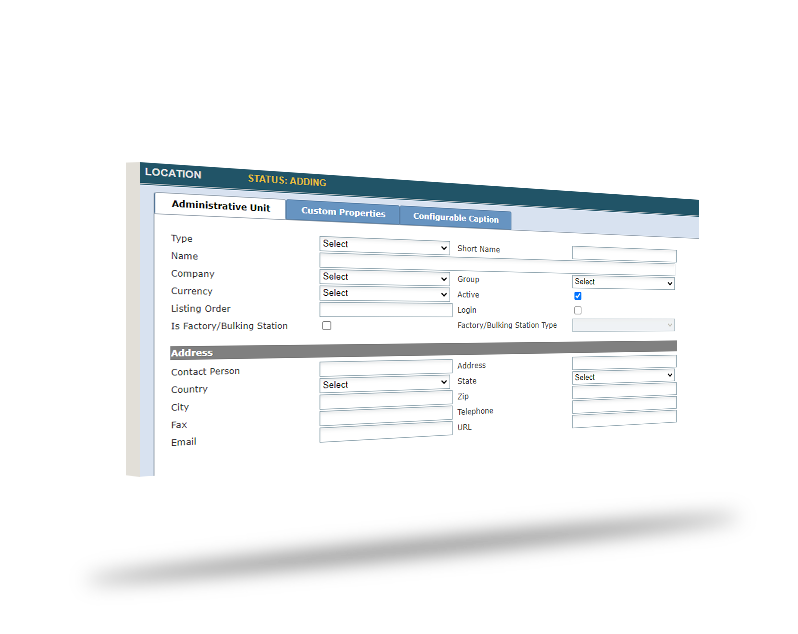

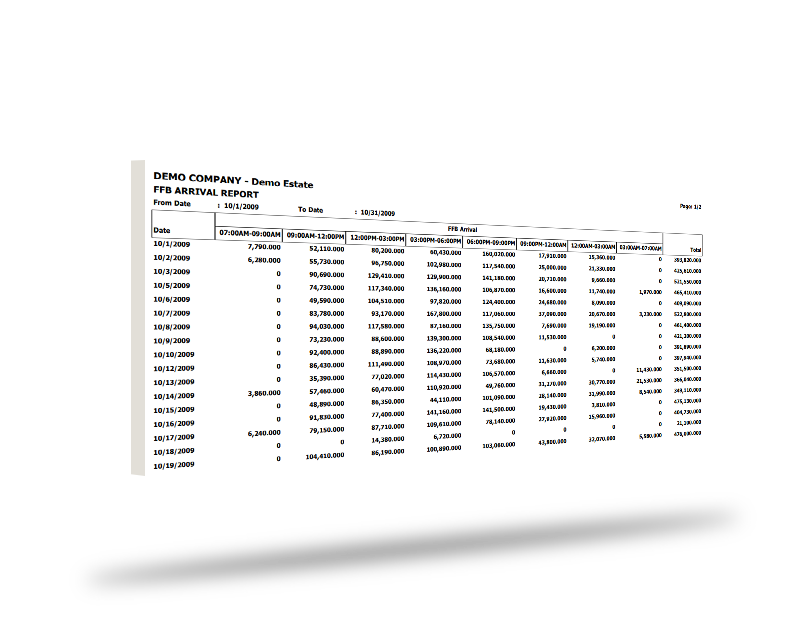

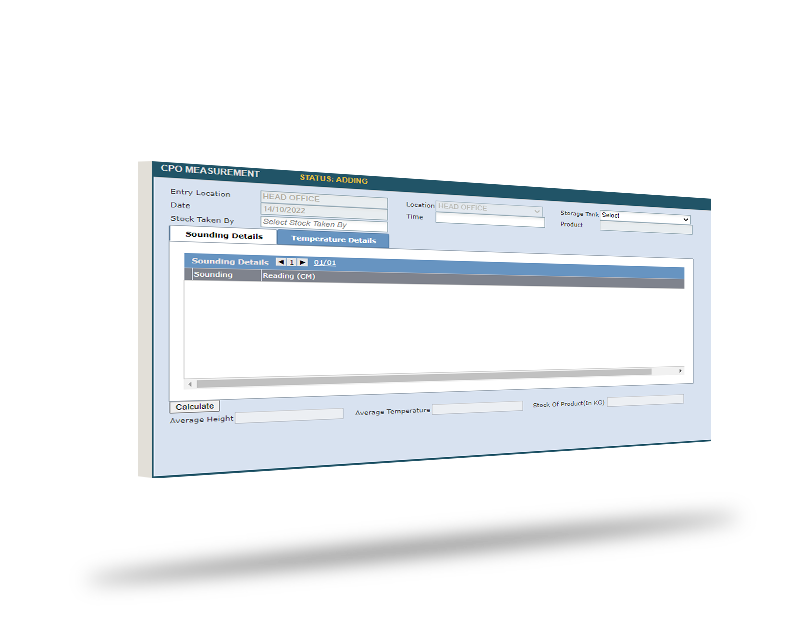

Product Details and Screenshots

Modular Features

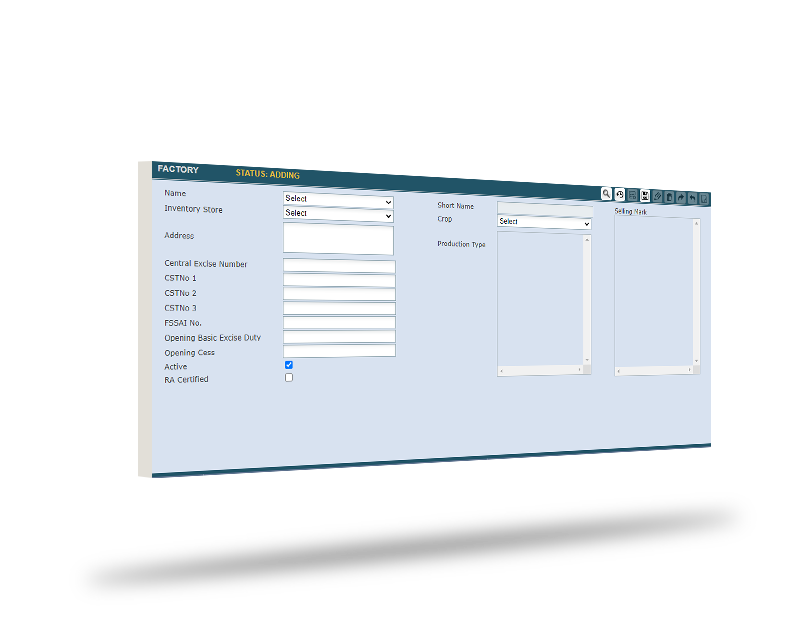

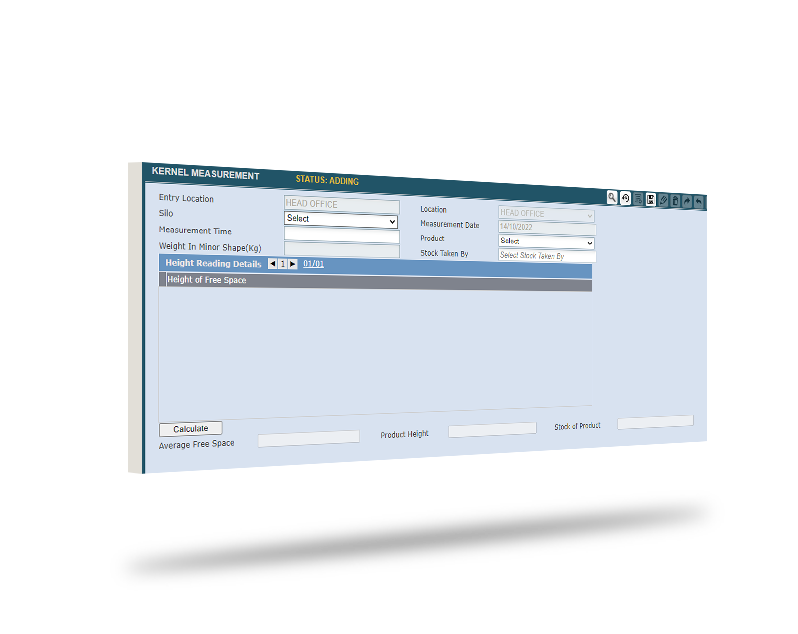

– Maintenance of various process stations, process sections, and process sub sections for the mill.

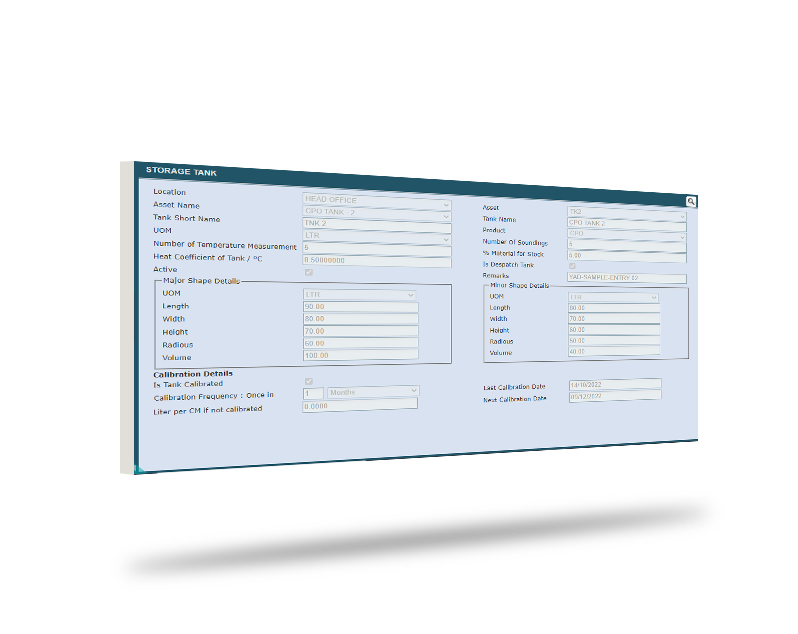

– Maintenance and management of various shapes of storage tanks and silos. It can be a combination of two or more geometrical shapes.

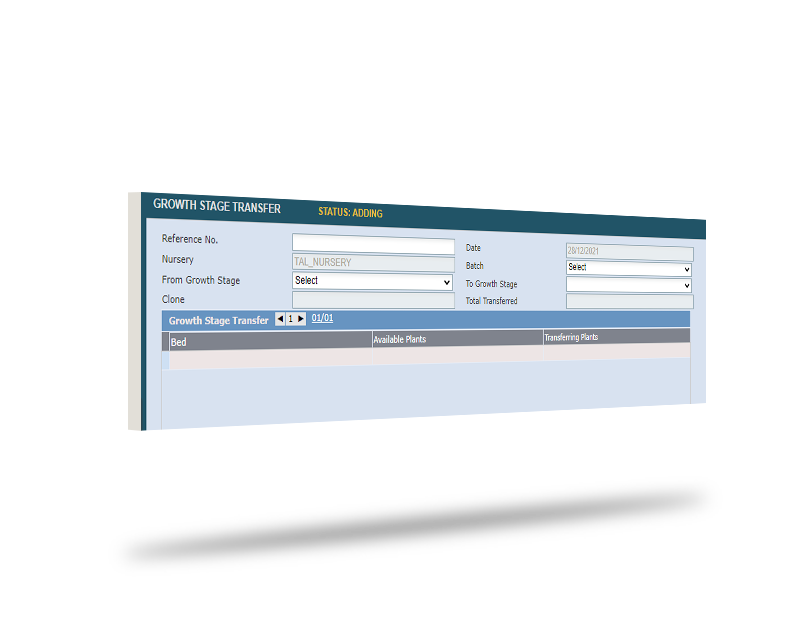

– A complete track and traceability of the arrival of FFB (fresh fruit bunches) to the mill from various sources.

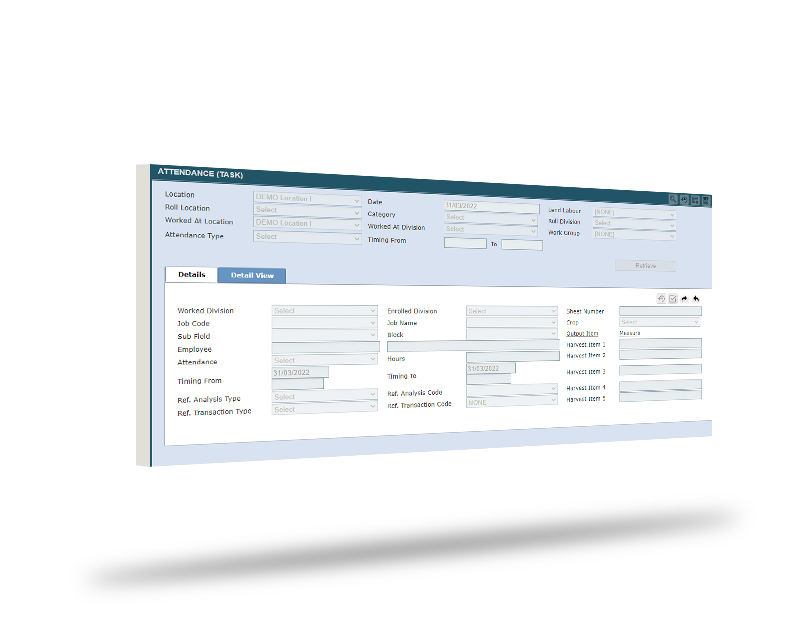

– Complete capturing of harvesting of FFB and integration with payroll system covering incentive, penalty, tasks, and salary disbursement.

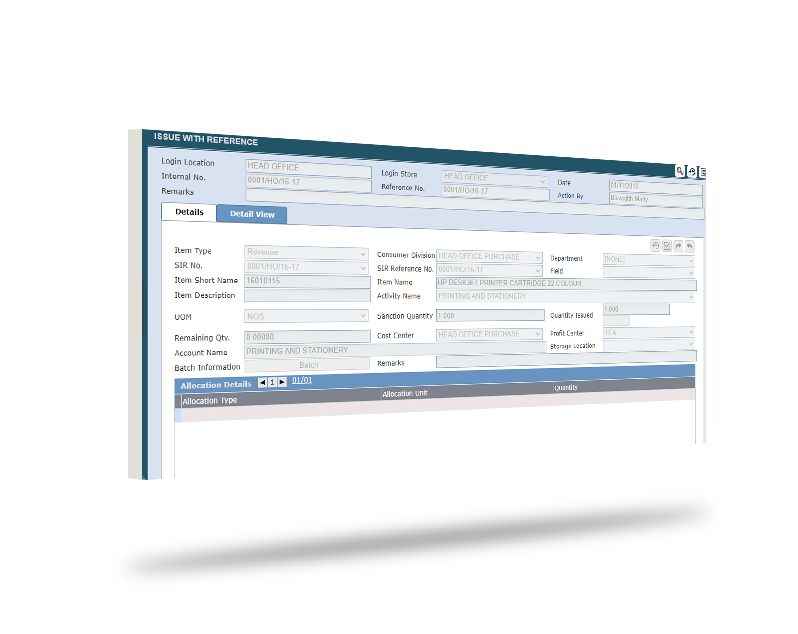

– Fully digitalized employee details from hiring, leave management, salary computation, production, storing semi-finished and finished products, dispatch, and sale.

– Recording and maintenance of specific gravity and calibration charts.

– Holistic perspective and quality analysis of finished and semi-finished products using various test parameters.

– Detailed stock maintenance of semi and finished products such as CPO, CPKO, PK.

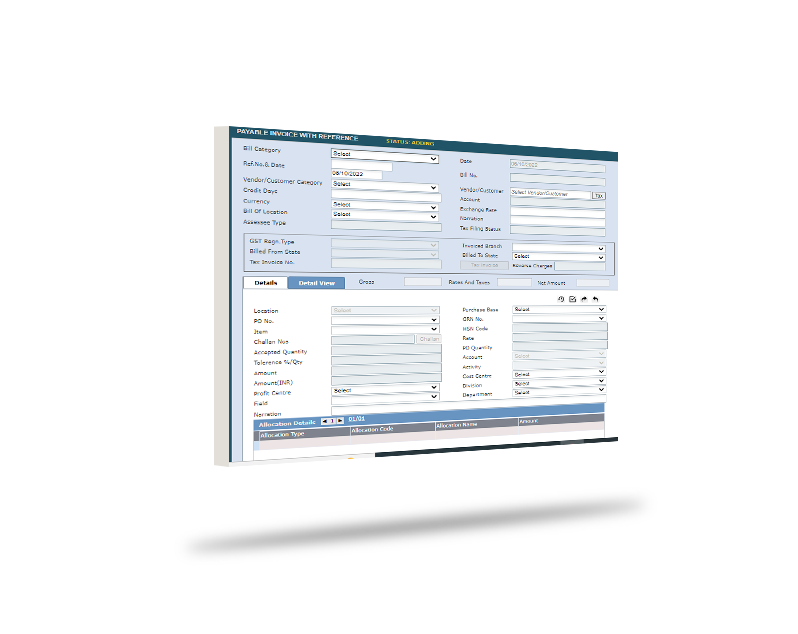

– Data control mechanism to authenticate and verify dispatches from the Mill.

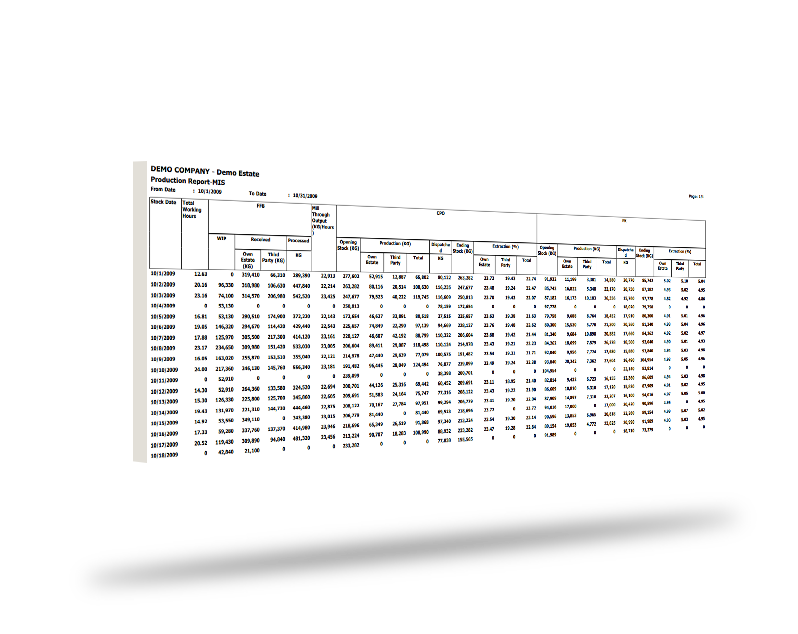

– Calculation of extraction ratio of the product derived by considering the FFB processed.

– Integration with bulking stations or tank farm management systems.

– Capturing machinery log with respect to the down time, restart time, and breakdown incidents.

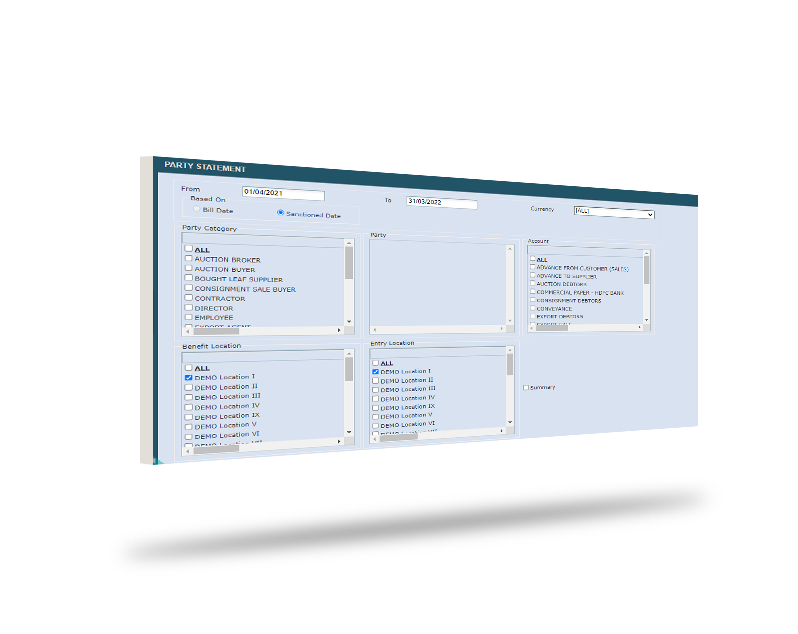

– Advanced reporting structure to analyse mill or factory data to get a better perspective of the operations.

Sankalp Sahi

Senior Manager IT – Vietnam India Laos, Olam Food Ingredients, Vietnam

Jeganathan Ramanatham

Finance & Admin – Manager, Outspan Bolovens Ltd, Srilanka

Apurba Bhattacharyya

Deputy General Manager | Systems, Apeejay Tea Group, India

JITHIN P R

Project Coordinator | Harvest Plus Support, olam food ingredients, Zambia

Rezaul Islam Bhuiyan

Head of IT and MIS, The Consolidated Tea and Lands Company (Bangladesh) Limited

Clients that use our products

1,500+ organizations trust us with their business and software solutions